The injection moulding process is ideal for rapidly fabricating plastic parts, components, and products at a large scale. Plastic injection moulding is a crucial manufacturing technique with millions of users – it may be used to make anything from car dashboards to medical devices. With robotics being integrated into the process, new precision, efficiency, and innovation opportunities have opened up. Moulded commodities are obtained by injecting plastic materials molten by heat into a mould, lowering the temperature, and solidifying them.

Examples of industries that benefit from plastic injection moulding include but aren’t limited to medical, pharmaceutical, telecommunications, consumer products, packaging, food and beverage, automotive, and building and construction. It’s a manufacturing process that has earned its rightful place in the business of any production company. Getting a good understanding of the specifics of injection moulding will help you make a more informed business decision for your outputs. Irrespective of the complexity of your goods, you enjoy complete control and flexibility when it comes to design.

Structural Foam Moulding Is an Excellent Alternative, Offering Adaptable Solutions for Various Industries

Injection moulding is the most common modern method of manufacturing plastic parts, yet you must envision all the possibilities. Structural foam moulding is one such example. If you have a new business and look forward to going into full production, leverage low pressure structural foam moulding for the development of plastic parts because it delivers results with the least amount of input and enhances the attributes of the raw materials. The low-pressure process makes use of a dedicated special-purpose injection moulding machine, which introduces gas into the melted plastic, which aids in the fill and pack-out of the mould. Roughly all thermoplastic materials can be foamed.

Businesses Use Injection Moulding for Its Cost-Efficiency, Versatility, Precision, And Scalability

Injection moulding is a manufacturing process that facilitates the fabrication of plastic products in large volumes; it’s highly controlled, and material usage is optimised, which results in minimal waste. As a rule, plastic injection moulding is used to produce countless identical items. There are several considerations to bear in mind in terms of manufacturing process selection, namely financial, production quality, design factors, and production considerations. You also need to be aware of your market area and its ever-shifting demands. Injection moulding has numerous benefits and perks supporting its reputation as one of the best methods for manufacturing for manufacturing plastic parts, such as:

Huge Amounts of Product Can Be Manufactured from Just a Single Injection Mould

Closely considering manufacturing costs like materials, direct/indirect labour, utilities, and inventory can help increase the total revenue generated by the company, not to mention the profits for the organisation. Compared to other manufacturing processes, injection moulding produces excellent results without costing a lot of money. Following the initial investments in the moulds and the machinery, the cost per unit decreases significantly for larger production runs. In other words, plastic injection moulding is expensive to set up but is cheaper in the long run, so it’s suitable for large production volumes. The automated nature of the process eliminates the need for extensive manual intervention.

Injection Moulding Demonstrates Remarkable Versatility and Precision

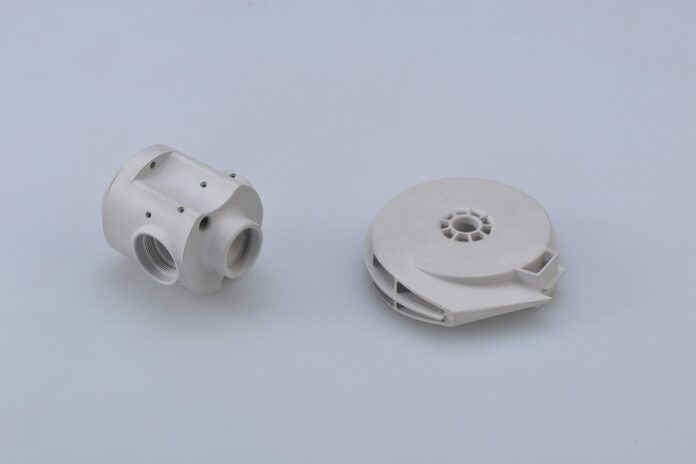

The injection mould undergoes high pressure, meaning the plastic is pressed harder against the mould, making it possible to add various details to the design. Companies can create intricate and complex designs that otherwise wouldn’t be possible to obtain. The design flexibility lies in the generation of precision machine parts, sophisticated features, and varying thicknesses. It doesn’t come as a surprise that injection moulding has gained traction in industries such as automotive, electronics, medical devices, and consumer goods. You can find services that specialise in metal fabrication near me to take advantage of this highly versatile manufacturing process, enabling businesses to produce highly detailed and repeatable finished goods, improving the output’s uniformity and quality.

Manufacturers Can Choose from A Wide Range of Plastic Materials

The exceptional versatility of injection moulding allows manufacturers to select materials that address specific performance requirements (strength, durability, and temperature resistance). Some of the most popular moulding materials are crystalline, semi-crystalline, and amorphous thermoplastics. More often than not, material selection is a guessing game, as there’s a gap in the understanding of the elementary relationship between the internal structure of the materials and their properties. Via careful selection of moulding materials, you can guarantee your products meet performance requirements while upholding cost efficiency. Have a few tests performed using the target material before committing to a mould.

Understanding The Ins and Outs of How to Set Up an Injection Moulding Process

Provided you have the capital to support a startup, proceed with the construction of the plant, leaving roughly 1000 square feet for each moulding press. You can rely on robotics and automation to perform the tasks that would otherwise be carried out manually. Robotic systems, in their quest for perfection, complete tasks optimally with minimal resources, streamlining faster production cycles and consistent output. You’ll need space for the storage of moulds that aren’t currently in use, besides bags and gaylords of material. Some moulders, due to the nature of business, store raw materials on the shelf, which can easily lead to overcrowding.

For the sake of clarification, tackling challenges in-house can engender inefficiencies, bringing about costly, time-sensitive problems despite efforts to streamline the process. The point is that if you’re contemplating the idea of implementing injection moulding into your business, outsourcing may be worthwhile. Producing high-quality plastic parts, components, and products requires knowledge and expertise, so the job is better left to the pros. When you work with an established manufacturer, you have a guarantee you can produce first-grade items using value-added services. The best services can be identified by their portfolio, customer reviews, and quality assurance certificates.

Conclusion

All in all, injection moulding is becoming more environmentally friendly as machines are becoming more efficient and polymers become capable of withstanding extreme temperatures and conditions. Injection moulding is a popular technique used across various sectors because it’s reliable, highly efficient, and can be adequately controlled. The adaptability of the manufacturing method, combined with its design flexibility, makes it a suitable choice for companies seeking efficiency and cost-effectiveness in their production processes.