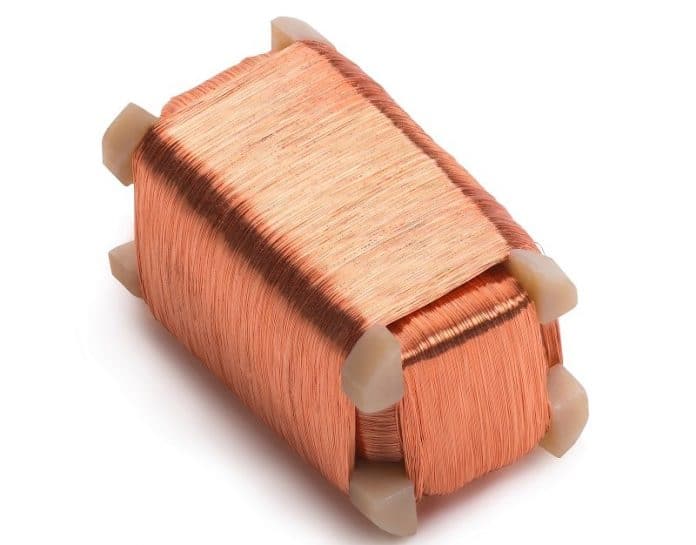

From this article, you can learn about the process of winding coils for standard and micro medical sensors. In the coil winding process, the wires do not come in contact with each other. Instead, manufacturers wind them around a core. Before winding coils, they coat the wires for insulation purposes and to ensure that the wires stay separated from each other. This process thus generates electromagnetic induction. The use of copper is most frequent in winding coils and each copper wire comes with proper insulation coating (polyamide-based material for insulation) that can resist voltage breakdown and high temperature.

The difference among coils:

The most significant difference between the coils is their difference in shape. This also deflects their electrical values as well. In general, these below forms are most common in winding coils.

- Elliptical.

- Round.

- Rectangular.

Besides it, another decisive factor in the coil winding process is the measurement of the diameter of the coil (from inside and outside).

The procedure of coil winding for medical-grade sensors:

Size plays a very important role in winding coils for medical purposes. Miniature coil-based medical sensors mainly go inside our body, such as inside our vein. For that reason, the size of the coil can’t be larger than 0.8 mm, which also includes the coating. To reach this optimum preciseness, you need to use custom-designed, in-built machinery which you will not get in the open market.

We can make a coil by winding copper wires around a core. However, some other types of coil making processes are;

- Self-bonded and coreless coils.

- Winding wires in rectangular or square shape and then removing the square or rectangular core, leaving only the coil.

The process of preparing micro-coils:

If you want to manufacture micro coils for miniature medical sensors, you certainly need the below things;

- Good knowledge about the micro-coil winding process.

- Customized machinery unavailable in the open market.

- Highly skillful engineersa and designers.

The micro coil winding process requires in-house engineering, which means you need to engineer the machines by yourself in order to make micro coils. Each and every process in micro coil winding (such as soldering, joining wire terminals) requires specialized equipment that you need to make in-house.

To maintain flawless connectivity within microsensors, you need to use super-tiny wires, which necessitates the interaction of multiple inventive technologies. Following a strictly monitored method and utilizing these unique technologies, copper wires are handled to attain the desired diameter, which can be as fine as 0.00035 inches. Properly controlling a wire with such a miniature design is not an easy job and thus requires a high-tech micro-motion and organizing system. For that reason, very few companies in the world manufacture micro coils for miniature medical sensors. However, due to the vast usability of these sensors, now their need is increasing around the world. So, we can expect steady growth in this sector in the future years.

From this article, you can learn about the process of winding coils for standard and micro medical sensors. In the coil winding process, the wires do not come in contact with each other. Instead, manufacturers wind them around a core. Before winding coils, they coat the wires for insulation purposes and to ensure that the wires stay separated from each other. This process thus generates electromagnetic induction. The use of copper is most frequent in winding coils and each copper wire comes with proper insulation coating (polyamide-based material for insulation) that can resist voltage breakdown and high temperature.

The difference among coils:

The most significant difference between the coils is their difference in shape. This also deflects their electrical values as well. In general, these below forms are most common in winding coils.

- Elliptical.

- Round.

- Rectangular.

Besides it, another decisive factor in the coil winding process is the measurement of the diameter of the coil (from inside and outside).

The procedure of coil winding for medical-grade sensors:

Size plays a very important role in winding coils for medical purposes. Miniature coil based medical sensors mainly go inside our body, such as inside our vein. For that reason, the size of the coil can’t be larger than 0.8 mm, which also includes the coating. To reach this optimum preciseness, you need to use custom-designed, in-built machinery which you will not get in the open market.

We can make a coil by winding copper wires around a core. However, some other types of coil making processes are;

- Self-bonded and coreless coils.

- Winding wires in rectangular or square shape and then removing the square or rectangular core, leaving only the coil.

The process of preparing micro-coils:

If you want to manufacture micro coils for miniature medical sensors, you certainly need the below things;

- Good knowledge about the micro-coil winding process.

- Customized machinery unavailable in the open market.

- Highly skillful engineersa and designers.

The micro coil winding process requires in-house engineering, which means you need to engineer the machines by yourself in order to make micro coils. Each and every process in micro coil winding (such as soldering, joining wire terminals) requires specialized equipment that you need to make in-house.

To maintain flawless connectivity within microsensors, you need to use super-tiny wires, which necessitates the interaction of multiple inventive technologies. Following a strictly monitored method and utilizing these unique technologies, copper wires are handled to attain the desired diameter, which can be as fine as 0.00035 inches. Properly controlling a wire with such a miniature design is not an easy job and thus requires a high-tech micro-motion and organizing system. For that reason, very few companies in the world manufacture micro coils for miniature medical sensors. However, due to the vast usability of these sensors, now their need is increasing around the world. So, we can expect steady growth in this sector in the future years.