VLSI design lies at the heart of modern electronics, powering everything from smartphones to supercomputers. Understanding the intricacies of the VLSI design process is essential for engineers and enthusiasts alike, as it encompasses a series of meticulous steps to transform concepts into silicon reality. In this blog, we’ll journey through the various stages of the VLSI design flow, shedding light on each crucial step.

The growing importance of Very Large Scale Integration (VLSI) has transformed it into a coveted career choice for design enthusiasts. Demand for skilled professionals escalates as VLSI drives innovation in electronic devices, from smartphones to IoT gadgets. Undertaking a VLSI course equips individuals with essential knowledge and skills for this field. Covering semiconductor physics, digital and analogue circuit design, and CAD tools, such courses provide practical experience through projects and internships. Moreover, VLSI courses emphasize emerging technologies like SoC design and low-power techniques, fostering expertise crucial for success in VLSI careers. Ultimately, VLSI courses pave the path to fulfilling and impactful semiconductor design and innovation careers.

What is VLSI design?

Very Large Scale Integration design comprises the creation of integrated circuits (ICs) that hold thousands to billions of transistors on a solitary chip. This intricate process encompasses designing and implementing complex electronic systems while optimizing performance, power consumption, and cost. VLSI design spans various stages, including architectural design, logic design, circuit design, physical design, and verification. Engineers utilize specialized tools and methodologies to translate system specifications into functional silicon chips, ensuring they meet stringent performance criteria and industry standards. VLSI design is critical in advancing technology, enabling the development of smaller, faster, and more efficient electronic devices across various applications, from smartphones and computers to automotive and aerospace systems.

VLSI Design Flow

The VLSI design process involves creating integrated circuits (ICs) with millions of transistors on a single chip. It encompasses stages such as architectural design, logic design, circuit design, physical design, and verification. Engineers use specialized tools to translate system requirements into chip layouts, ensuring functionality, performance, and power efficiency. The process involves meticulous planning, simulation, and testing to meet design specifications and industry standards. Ultimately, VLSI design enables the development of sophisticated electronic devices that power various industries.

The VLSI design flow comprises numerous steps, each fulfilling a specific role in the design process. Now, let’s explore the essential stages of the VLSI design flow:

Specification:

The specification stage marks the beginning of the VLSI design process. Here, designers work closely with stakeholders to gather and define the requirements and constraints of the desired integrated circuit (IC). This includes determining the functionality, performance targets, power requirements, area constraints, and any specific features or standards the IC must adhere to. Clear and precise specifications are crucial as they form the basis for subsequent design decisions and ensure alignment with the intended application.

Design Entry:

In the design entry stage, designers translate the gathered specifications into a high-level design representation. This involves creating a conceptual design of the IC’s architecture, logic, and functionality using hardware description languages (HDLs) like Verilog or VHDL. Designers may use schematic capture tools or write HDL code to describe the behaviour and structure of the IC. The goal is to capture the logical functionality of the IC in a manner that can be synthesized into physical hardware components.

Verification:

Verification is a critical stage aimed at ensuring the correctness and functionality of the design before proceeding further. Designers employ various verification techniques such as simulation, formal verification, and emulation to validate the design against the specified requirements. This involves running extensive tests and simulations to detect and resolve any design flaws, logic errors, or functional bugs. The verification process helps minimize the risk of errors and ensures that the final IC meets the desired functionality and performance targets.

Synthesis:

Synthesis is the process of transforming the high-level design description into a detailed gate-level representation that can be implemented in hardware. Using synthesis tools, designers map the logical description of the IC onto specific hardware components such as logic gates, flip-flops, and registers. Synthesis involves optimizing the design for factors like area, power, and timing to meet the specified constraints. The output of synthesis is a netlist, which specifies the interconnections and logic elements of the design at the gate level.

Fabrication:

Fabrication, also known as manufacturing, is the stage where the physical IC is produced based on the synthesized design. This involves transferring the design layout onto silicon wafers using photolithography and semiconductor manufacturing processes. Fabrication facilities (fabs) use advanced equipment and techniques to etch, deposit, and pattern multiple layers of materials onto the silicon wafer to create the integrated circuit. Fabrication is a highly complex and precise process that requires meticulous attention to detail to ensure the production of functional and reliable ICs.

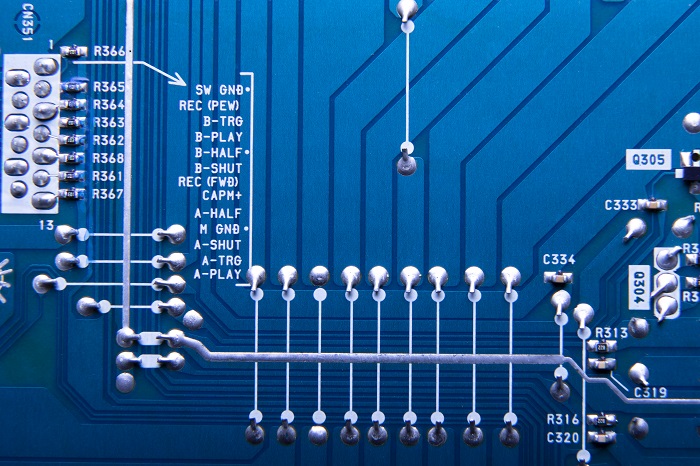

Layout:

The layout stage involves creating a detailed physical layout of the IC’s components and interconnections based on the synthesized design. Designers use computer-aided design (CAD) tools to place and route the individual components (transistors, gates, interconnects) on the silicon die while adhering to design rules and constraints. The layout process includes optimizing the physical placement of components to minimize area, reduce power consumption, and meet timing requirements. The final layout is a blueprint that guides the fabrication process and determines the physical structure of the integrated circuit.

Conclusion

Unravelling the intricacies of the VLSI design flow unveils the foundational steps crucial for creating sophisticated integrated circuits. Understanding these key stages is paramount for aspiring professionals seeking to venture into the dynamic world of semiconductor design. Pursuing a VLSI course serves as a pivotal stepping stone towards building a rewarding career in the rapidly growing design industry. By mastering the intricacies of VLSI design through comprehensive education and practical experience, individuals can acquire the skills and knowledge necessary to thrive in this fast-paced and innovation-driven field, shaping the future of electronics and technology.